Stop Global Collapse!

The Answer is Distributed Manufacturing.

Done on low-cost 3D printers.

CHINA IS GOING OFF-LINE, too! Turn off your long supply lines. Lower the cost of goods to consumers. Get people designing and innovating again.

“How?”

With Ultra-Make.

We’re a new business model: We champion “emailable” products. Things the new Maker Class of Designers and next-gen Manupreneurs can sell to customers online for local printing at the end use location.

No factory in Asia. No environmental waste or overhead.

Just a new class of products based on standard 3D printing and PCB routing standards, coupled with a few forward-thinking parts houses.

“Wait -email ACTUAL products?”

You bet!

New to “Making” are you? We’re here to help.

This website is dedicated to “disrupting the Old World Order” by promoting local manufacturing. Yes: Desktop Manufacturing is real.

Thing is, most people don’t know about sources like Yeggi and Thingiverse. Great sites! But, where’s the integration? That’s where we fit in.

The main problem? People are not clear on the technologies of desktop manufacturing. Maybe they have one machine. But is “that all there is to the circus?

We’re here to up everyone’s game.

One-print, one-machine…yeah, sure, interesting. But can we get to the grown-up builds? The ones with print files, g-code, instructions, and a back to components coming next day in the mail?

Empowering Designers and next-generation Online Manufacturers to offer absolute top-notch products to markets with zero lead-time.

And fewer strings to Asia.

We won’t pretend to give you rhyme and verse of G-Code which runs a lot of desktop machines. We focus on the “High level View.” In grad school, this would be the Management course or Business Model discussion.

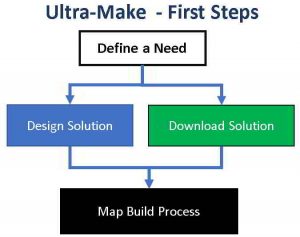

Ultra-Make is a simple series of processes to online DIY Designers and Makers can take products to market in the least expensive, most direct means possible.

Somewhere, in following these little “process maps” around, a light will go on in your head.

“Hey! You mean I can invent or design something, and then sell it online in direct competition with some mega-giant corporation somewhere?”

Exactly so!

Because above all else, legends of management science, like Frederick Winslow Taylor, made mountains of money for people by doing “time and motion studies” or working people.

This site will help you think more like a Manager and get you looking at In-Home Manufacturing (for that’s what this subversive little website is all about!) as a manager would.

Everything in manufacturing is measurable and repeatable.

How this Site Began

The author of this site is a quirky fellow who is mainly a writer and hobbyist whose hand tool collection is pretty good.

In his shop, there’s an area for metal-working. 9X20″ geared head lathe, small desktop manual milling machine, Fair-sized box and pan sheet metal bending brake, plus gas, wire, and stick weldets with a 1/2″ clean-cutting plasma machine and a metal-cutting chop saw. A small Taig lathe for fine work.

Sounds like a lot of fun, already, doesn’t it?

Over in the corner somewhere, there’s also a Backyard Metalcasting melting furnace waiting to be built.

Sure, there’s a woodworking side of this “dream shop” as well. A couple of belt sanders, drill press, planer, band saw, table saw, 12″ compound chop saw and even a central vac system.

BUT the problem I ran into was there have recently been a handful of “I want to build that’s…” I can’t do simply even with the big investment in equipment.

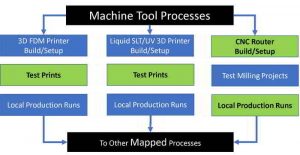

You need CNC…or something that would get “close enough.”

While the web is great on the “drill-down” stuff, the high-level is missing. At age 71, here comes a new research project – which is what this site is.

You’ll find some of the videos that helped me sort out wheat from chaff. And you’ll find some vendors I’ve bought from plus the various Youtuber’s who’ve done the videos that make it possible to come up-to-speed quickly.

The Big Geekly Vision

Ready?

You get up tomorrow morning, hit Amazon and want to build a new audio amplifier.

Sure, you can buy one premade and from China. But, is that going to help anyone in America?

What if you could buy a pretty good audio amp and just download it?

Here’s what the “Making” process looks like for this new Amp of yours:

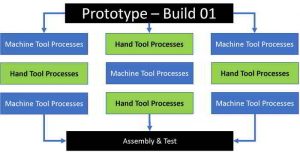

-

- You order and pay.

- Three files are pushed out to you.

- Two files for the Amp housing (Top.stl and Bottom.stl)

- One file to mill the printed circuit board.

- A day later, a small package arrives from an electronics supplier. Inside are all the electrical components, connectors, and devices to complete your build…

While your 3D printer works on the second half of the case, you notice the PCB milling is completed over on the CNC router.

You, dear reader, are about to be an ultra-maker.

Or, if you like the process, maybe you’re a designer?

With online parts-picking a reality, you think back to the recently revitalized Heathkit and how they revolutionized America with high quality kits in the 1950’s and 1960’s.

Could it happen today?

Let us email you a product, one of these days, or better yet, you email us one.

The Old Paradigm: Polluting factories in China, massive shipping overhead, cutting down rainforests for packaging materials…all going…going…

Dispersed neighborhood manufacturing (DNM) is at hand. And you’re getting there first.