When I published the first “Case #1 of The Electronic Detective” long before branching off the Ultra-Make site, the idea was – in our first episode, we will tackle a medium-complexity problem in electronics – there have been dozens of additional cases which might be of interest to an electronics aficionado. But unfortunately there is only so much time and so much energy to write up highly specialized learnings.

But to be sure, a review of microprocessor-controlled antenna tuners, insights into common grounding of towers and ham station grounding systems, not to mention some insights into “grounding the longer wire in OCFD antennas as an RFI prevention strategy” might not be of general interest. Though, I confess, they may appear as additional episodes here on Ultra-Make in the future. Because each has revealed a key lesson about electronics.

This weekend, The Electronics Detective returns with another Conan Doyle meets John Fluke adventure. Because, frankly, except for the economic implications of a Kansas City Super Bowl win, for most of us, it’s just another weekend…

A 16-Year Wiring Error (#136)

(Staff Announcer: “The story you are about to hear is true. The names have been changed to protect the innocent.”)

“I was working the day watch out of Electricide…“ began the raspy voice, as the late action-hero Det. Joe Friday began to lay out one of his major investigations.

“My partner and I had been chasing a suspected wiring violator in a 16-year-old solar power installation. Our discovery of the evidence, lost more than 16-years, came nearly by accident.

When we arrived on the scene, witnesses told us a 20-amp breaker had started to pop. This only seemed to happen when an under-wired 6,000 watt solar array- that had been recently rewired using MC4 solar connectors in place of Kearney bolts – was brought on line in full grid sell mode.

My partner, Bill Gannon at the time, thought the Bouge RV crimp on connectors had increased the total system output so much that now, when the sun was fully on the panels, one of the four 20-amp breakers kept dropping.

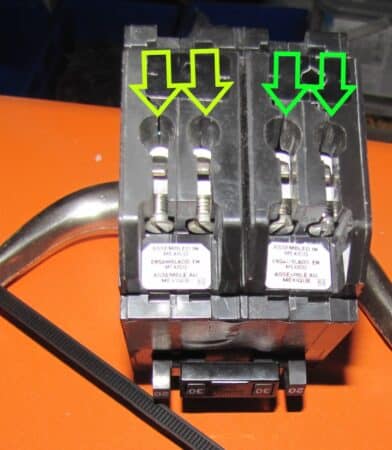

My partner – Gannon had a photographic memory- made some notes on what we were facing. An aging Square D Homeline panel with two poles and two tandem 20-amp breakers to handle 40-amps in all.

Gannon was a bit off that day, said his memory was flawed, so he drew the new install after the dual tandem 20 change. He then drew a yellow line on each side indicating the split in the middle of the old single tandems from memory here.”

Two Poles Per Breaker

“It didn’t take long to piece together how the ancient wiring error had been made. The electrician on the job, according to neighbors, was a lazy, no-good day trading technical analysis clown. Claimed to be some highly successful Business School genius. You know the type. Financial districts are full of ’em.

This character had obviously blanked out – while deep in a wiring trance, and didn’t remember that each leg of the 240-volt circuit powered not one, but two wiring points on tandem breakers.

[Non-Electricians note: The “Red Leg” top left fed the single tandem breakers on the left (light blue arrow)(. While the “Black Leg” fed the single tandem breaker on the right indicated by the yellow arrow.]

“As it became clear who our current suspect was, I decided the best way to serve justice would be to install a two pole, double tandem breaker of slightly higher capacity. And with a nod to South L.A. residents, we’d specify a ganged dual tandem singles unit.”

“Joe, it’s Thursday. Let’s go into this Podunk town and look around. See what we can find…”

“Good call, Bill.”

The counter expert at a local dealer electric supply house/emporium said he was aware of a suspect matching our description,

“Yeah, I know the guy. He was just in a day, maybe two back. Insisted we sell him a dual tandem quad unit.”

“Can you be a little more specific, for us?”

“Yeah. I remember he said either ganged 30’s or a pair with a 30-20 split on either side. Told he we had the quad ganged 30s with 20s either side. Went for it right away. Funny thing, though. Paid with a credit card. Hardly anyone does that anymore. Lately, people come in asking if we have a wallet.”

“The perp went back the following day and picked up another (20-30-30-20) and some #10 wire intending to pig-tail with #10 off either of the 20’s. Because even the new breaker was still causing him, fits. As he just couldn’t seem to get two #12 wires into each of the outer breaker’s connectors:

“I flashed him my badge.

OK You, the slick talker and fast writer. My name’s Joe Friday and this is my partner Bill Gannon. We’re charging you with a Code 12-V section 30 A, conspiracy to distribute electrons without a permit.”

“What the fuck? That’s an L.A. County Badge. We’re in Texas. Little out orf your jurisdiction, aren’t you, Bud?”

“Intergovernmental cooperation. Get used to it. We may have shoplifters getting off Scot-free, home, people on drugs and crapping in our streets, but people like you – you mister – trafficking underaged electrons. You make me sick.

(Four beats of theme. FTB then logo up…)

Closing Credits

[Arial font, bold, chroma keyed over badge logo:]

The Fast Writer electron peddler was charged and convicted under Code 12-V section 30 A of the L.A. County Building Code. His case is now on appeal to the Mexico Supreme Court which claims functional jurisdiction south of I-40 in the former United States.

(Four more beats of theme, hold march horns to 30.)

“Are You Wired?“

All seriousness aside, this case was one of those “fortunate accidents” of Fate.

Because while the (Gomer) who did the original wiring obviously remembered that the Rule which reads “Inverter Legs go to Separate Legs” his failure was in not keeping top-of-mind that two wiring points, though separate, do NOT MEAN DIFFERENT LEGS. Only on conventional non-tandem breakers!

The use of #10 and a pigtail on the “outer 20’s) is an obvious safety choice considering how tight a pair of 20’s would fit the new breaker: The inverter, now on one yellow and one green arrow breaker (above) could then be pumped up and both legs should be able to sell-back power at a higher rate without blowing the breaker. (Resetting the Outback Power 24-volt FX/grid-ties to reflect higher max current buying and selling 30 aac each on the software menu.)

Here’s the Funny Part

This is one of those “funny, pain-in-the-ass stories” where the right solution would never have presented itself had the old Homeline tandem 20-amp breakers not failed during Attempt #2 to install things. As you can see (we took this to Forensics to have them put a ‘scope on it). The upper wire socket pincer would not retract far enough to allow for two replacement wires.

I twisted and reefed on that sliding metal and it would not move. I suspect that it may have failed in a moment of (perhaps) self-welding under very heavy current loading.

The Key Takeaway

“When you think you have found the problem, always go upstream of any wiring issue” is a good start. If this had been done 15-years ago, when the initial dual tandem 15-amp breakers were updated to 20-amps, the problem would never have occurred.

Yet now that it has, despite an investment of 6-hours of work to set right, it’s really quite Graceful how Universe provided this dandy Lesson in Life. Consider:

- The failure occurred during a period of warm weather.

- As a result of the failure, there was no heat in my office while this adventure was played out.

- Yet I must surely curry some favor with Universe because it was an unseasonably warm night to be without heat. Indeed, office heat never dropped below 62 F even with only inverter-backed-up lines (computers, satcoms, ham radio, and the backup freezer in the storage room) all working as designed. And why not? They are fed with two 30-amp #10 wired circuits.

There is no Magic.

Short stories from the LoG (Life of George) very much on point. About 1999 or there abouts, I found myself the head of sales and marketing at a company in Bellevue, Washington, by the name of SGC. Short for Stoner-Goral Communications. I’d already worked with the late Don Stoner when we were pushing the envelope on wireless data over radio with the half-cycle wireless modem technology Don had developed at Microperipheral Corp. This was before it became DSI which became Avaya and then lofted into the mega-billions category. Those are the “Please hold, I have an important call for this number…” people. I’m the first human ever to say that, BTW.

The late Pierre Goral was the president of SGC at the time. We were having a grand time selling high end commercial radio gear for places like Gakona, Alaska and places like where only one airline flies near Tonopah, NV. We had an important client coming in and we wanted to make sure everything was in good working order for our planned demonstration of an HF SSB manpack radio. This was an SG-715. Paramilitary gear – sold tons of it.

We went out into the large parking lot and open field (then) on the west side of the SGC building where Pierre made a call. “KMI, KMI, this is sailing vessel….” began Pierre. But the radio didn’t work. No joy raising KMI.

“Come on Pierre, let’s take it in the shop and maybe Woody (resident electronics genius at making things work) can figure it out.”

“Shh. Give me a second.” With that Pierre went through a personal checklist – evolved over several decades of being one of the world’s top engineers in single sideband technology.

Within less than a minute, he’d not only found the problem but also fixed it. Turned out to be a problem with the collapsible manpack antenna, not the radio itself. A new antenna from Bill in the stock room and we were back in business.

“Sailboat calling KMI, your callsign again?” came the reply from the marine operator in San Francisco. From standing in a field in Bellevue, Washington.

Pierre gave me a scolding look and one of the best lessons ever in electronics and the same extends to mechanical systems as well.

“George, there is NO MAGIC. You have to look at everything in this world as a physics problem. The physics isn’t what fails. It’s the people.”

No kidding.

R.I.P. Pierre,

Now go bang something,

George@Ure.net

I am somewhat baffled by current NEC and interpretations I am finding on the web. I am equally baffled by responses I get from installers.

The current NEC is promoting module level rapid shutdown systems for PV panels. The interpretations I am seeing claim that this requires microinverters, or a rapid shutdown module on each solar panel. This increases cost, complexity, and decreases reliability. As to whether these whiz-bang gadgets have any EMP resistance is not known, but I find it unlikely.

On a ground mount array. I would think that a load-break rated switch for each string (not module) located at the array, and again at the entrance to the building for the DC PV circuits would be a hell of a lot safer and more dependable than solid state radio controlled Chinese gadgets. I get the impression that the code was written by Chinese electronics manufacturers, or a firechief without much knowledge of maintaining electronics and batteries in harsh environments. Complying with these code restrictions are causing me to slow down on moving forward with a solar panel installation.

Excellent points – which is why I moved early (2008) and got through the bullshit paperwork as early as I could.

Several things, though.

If you read the fine print on many of the microinverters they do not have a capacity to operate grid-independent. IoW that will not work with no grid. Which pisses away half the value of such systems, in my simple-minded way.

Second, certain engineering Marxists forget that the ONLY reason for disconnect from the grid is to prevent backfeeding and killing a lineman doing upstream work.

The rest is powercrats trying to legislation away net metering and some of the early progres.

With the imminent death of pure EVs and eventual buildout of (sane) tribrids (mains power as ev, hybrid as fuel cells and done with hydrogen or fossil (user choice based on price/mile) we ain’t going anywhere in a hurry.

You will love this week’s Peoplenomics report because we get right into the economics of how the world is being one-worlded with economics…more on Wed.

Plus spendy micro inverters and disconnects don’t fix the lifespan issues weitdh the solar, so it’s just another Ponzi deal. The choices you are left with are a) go in early, lowball a rig, use it and get into insulation instead of making power or b) start an Amazon sized company then who gives a rats….

There may still be an NEC exception which allows you to ground mount the panels and put all the solar electronics in a dedicated building, then run an AC line to Ure residence, and blow off the rapid DC shutdown crapola. But, that runs up the cost significantly. Very frustrating. I look forward to Ure next week’s columns.

“George, there is NO MAGIC. You have to look at everything in this world as a physics problem. The physics isn’t what fails. It’s the people.”

Amen bro. Amen.

Amen..

And 90% of the time what fails is MECHANICAL, not electrical. “Electricide”? That’s a new one on me.

Interesting post today George. I keep thinking of something my master electrician great uncle always said. “Don’t learn electrical safety by accident.”. I think he stole it from some power company commercial though.

The final sentence resonates with me. It is not the “Insert the subject of choice here” that fails, it’s the people. Seems many come up short since they are not operating at maximum bandwidth. I am inspired by your wide range of interests and expertise.

I commend you on this 6 hour, as you stated, project where you were able to complete it with only 2 trips to town for parts. Well done.

Stay safe. 73

There are still more spares enroute via amazon and home despots, though, lol…

When you live sufficiently remotely, parts are often made or substituted for until it’s convenient to make a trip to town. When that trip happens, it ends up being exhausting, returning home in the wee hours after many, many errands!

Today, after finagling and soldering a connection inside a rats nest of an automotive fuse box with 160 external connector pins and 240 more inside, I’ll make a final connection with a wire nut. That should last until I can get proper connectors for my fix. There may only be 12 volts involved at up to 30 amps, but getting stuck in the middle of nowhere is not fun. This level of stupidly unnecessary complexity is the ruin of many otherwise fine cars!

Earplugs an an iFly gps were under 1 kilobuck

A new plane with all the glass cockpit stuff adds 20 kbux.

Time enroute? About the same.

But in the first case, the pilot knew he had to revert to airspeed, alti, and a chart.

In the second case troubleshooting electronics systems is no substitute for airmanship.

Though it’s a more rubust business model, lol.

Hence the $400 hamburger flights and the 240 connector pin nightmare.

People aren’t as clear-headed as they once were.

Update. Box is reinstalled with modifications and the car starts repeatably and runs well – except for needing to relearn driveability parameters. Now all I need to do is put the dash panel and console back together again.

Regarding aircraft, a glass panel may require a bit less effort, but steam gauges tend to fail one at a time rather than just going dark! That could be terrifying at night in mVFR or IFR conditions! Sure, there are tiny backups, FWIW. Redundancy matters, but simplicity does also when possible! I suppose I’m a bit old school and would rather do things the hard way just to stay sharp.

Here’s what happened on an Airbus A320 with three highly qualified pilots and four candidates for the type rating on board:

https://www.youtube.com/watch?v=04M63B1sv_Y

All due to undocumented “features” related to the flight computers. The aircraft finally was landed with two damaged engines and damaged airframe using the elevator trim alone. By some miracle, there were no injuries to anyone on board.